Qiming Machinery has been cast cone crusher wear parts for over 30 years. Our cone crusher liner manufacturing process is based on the American standard. Let us check how we cast cone crusher liners.

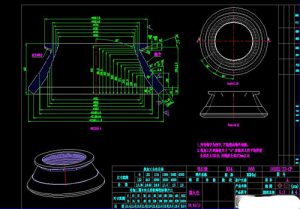

Step 1: Check the drawings with the customer, and translate the drawings

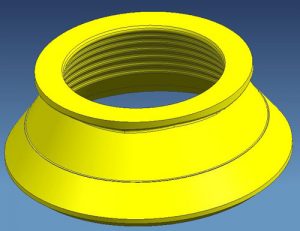

Step 2: Make a of the product is generated for better understanding

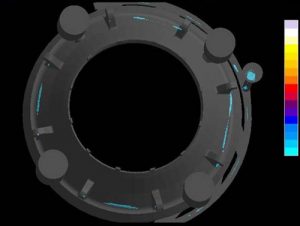

Step 3: Engineers make a design and produce documents to show the details: the heat treatment temperature, heat treatment time, casting temperature, casting time, keep the temperature-time…

Step 4: Make product models. Our models include steel model, wood pattern model.

Step 5: Start to prepare and analyze the raw material

Step 6:Products are poured using bottom pour ladle

Step 7: After cooling time, remove gating and risers, the goods start to heat treatment

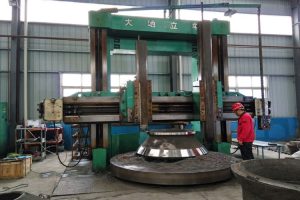

Step 8: Cone crusher liner Machining

Step 9: Printing and package