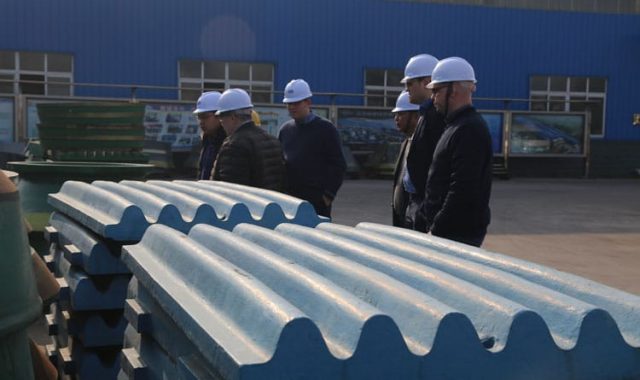

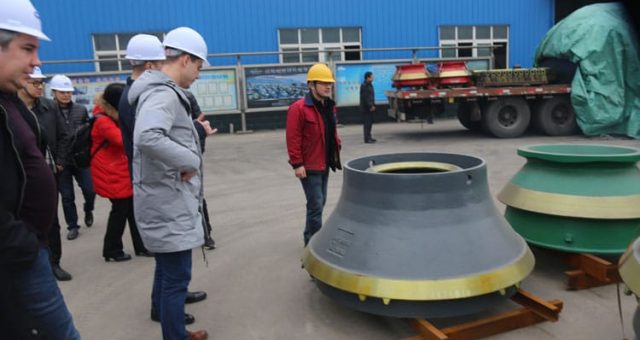

THE LEADING WEAR-RESISTANT MATERIAL CASTING FOUNDRY IN CHINA

Since founded in 2013, Nanjing Qiming Machinery had grown to a leading wear-resistant material casting parts manufacturers in China. With a total investment of more than $2,5000,000 and an area of 53,000 square meters.