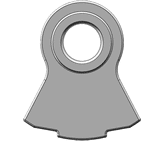

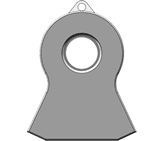

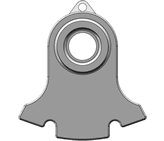

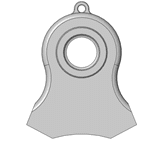

Shredder Hammers By Qiming Machinery®

When it comes to shredder hammers, Qiming Machinery has had manufactured high-quality shredder hammers for over 30 years. As shredder wear parts specialists, we have developed advanced alloys and manufacturing techniques that really pay off in demanding applications such as solid waste shredding. We stock an array of hammers and grates for common shredders, so you can normally get the parts you need in a matter of days.