Cone crushers are widely used in metallurgy, construction, mining, and other industries, and can be used as two-stage crushing or three-stage or four-stage crushing. Various vulnerable parts of hydraulic cone crusher, composite cone crusher, spring cone crusher are collectively referred to as cone crusher parts. Among them, mantles and concaves are also called cone crusher wear parts.

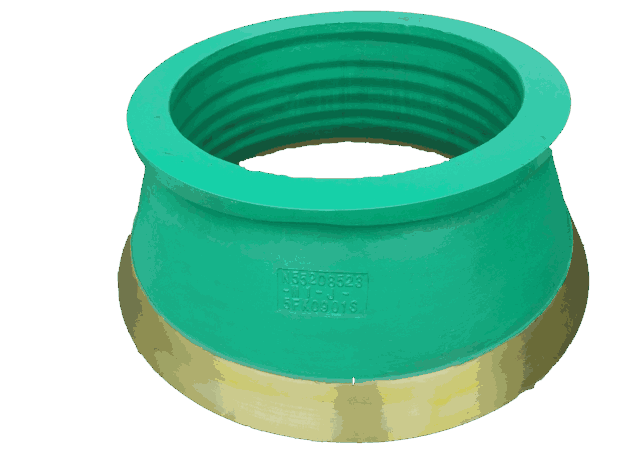

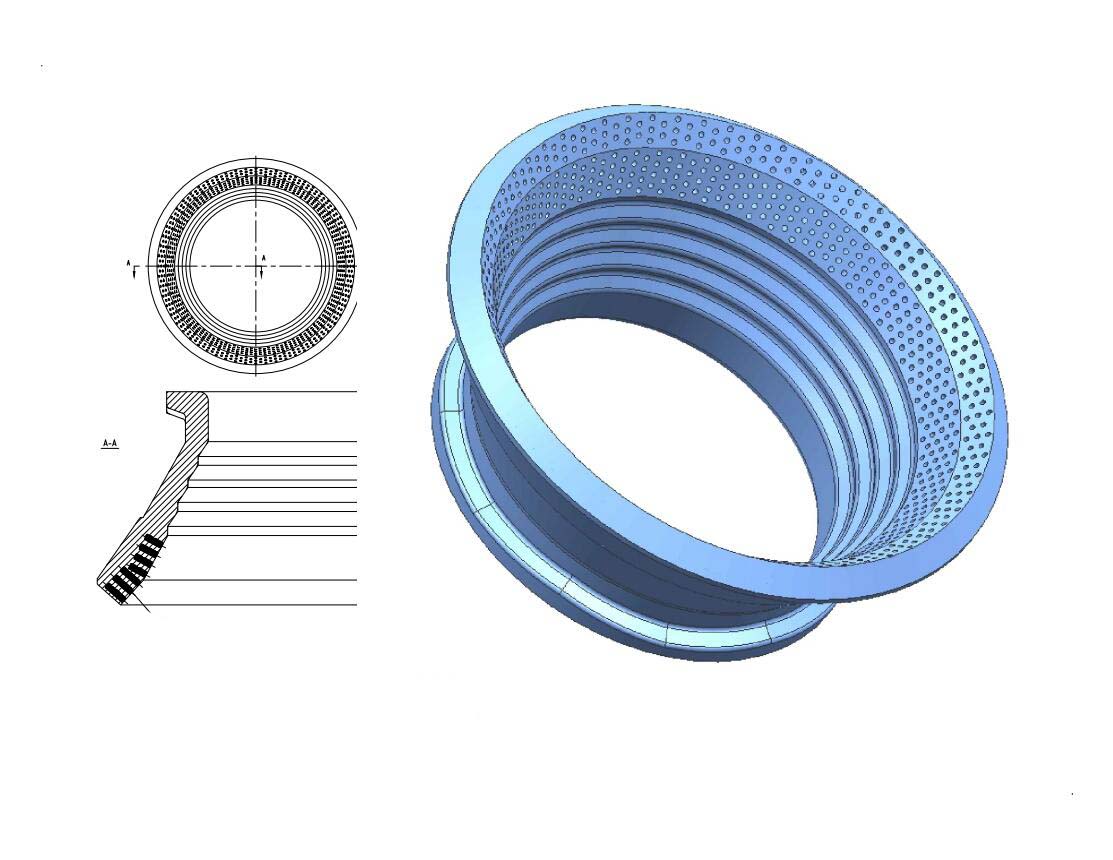

- Cone crusher mantle, which covers the cone head of the crusher to protect it from wear. It is the inner sacrificial wear liner that sits on the cone head.

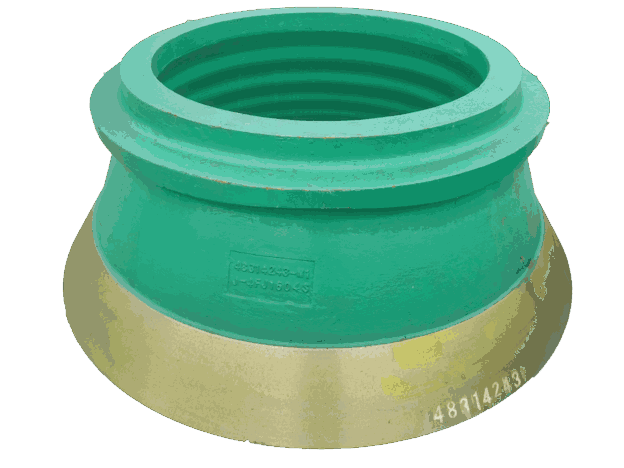

- Cone crusher concave, which sits in the upper frame of the crusher to protect it from wear. It is the outer sacrificial wear liner that sits inside the upper frame.

Cone crusher mantle and concave are also called cone crusher liners.

Cone Crusher Wear Parts By Qiming Machinery®

As a manganese steel foundry, Qiming Machinery had manufactured those cone crusher wear parts over many years. There are thousands of tons of cone wear parts are cast in Qiming Machinery. Qiming Machinery designs and manufactures standard, heavy-duty, and custom wear parts for all popular cone crushers. Our’s cone crusher wear parts provide the highest possible wear life combined with mechanical reliability and numerous mounting possibilities.

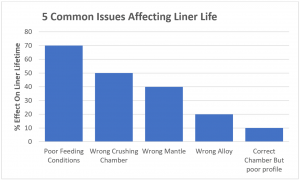

Our engineers improve wear parts life by modifying standard materials. On the other hand, our new TIC inserts wear parts can get 1.5 to 2 times span life than normal manganese parts.