Gyratory Crusher Wear Parts by Qiming Machinery®

When it comes to gyratory crusher wear parts, Qiming Machinery had manufactured those gyratory liners for over 30 years. The primary gyratory crusher wear parts have the most important role in rock size reduction in mine operations as the crushing process starts from a primary crusher. The highest possible wear life is combined with mechanical reliability through the component life cycle.

Our engineers are committed to understanding your specific needs and refining a solution to help you. To us, that means direct communication with you to get a full understanding of your wear part needs and on-site consultation if necessary. We have a wide range of gyratory crusher wear part designs in our database to choose from and customize.

Gyratory crusher wear parts include:

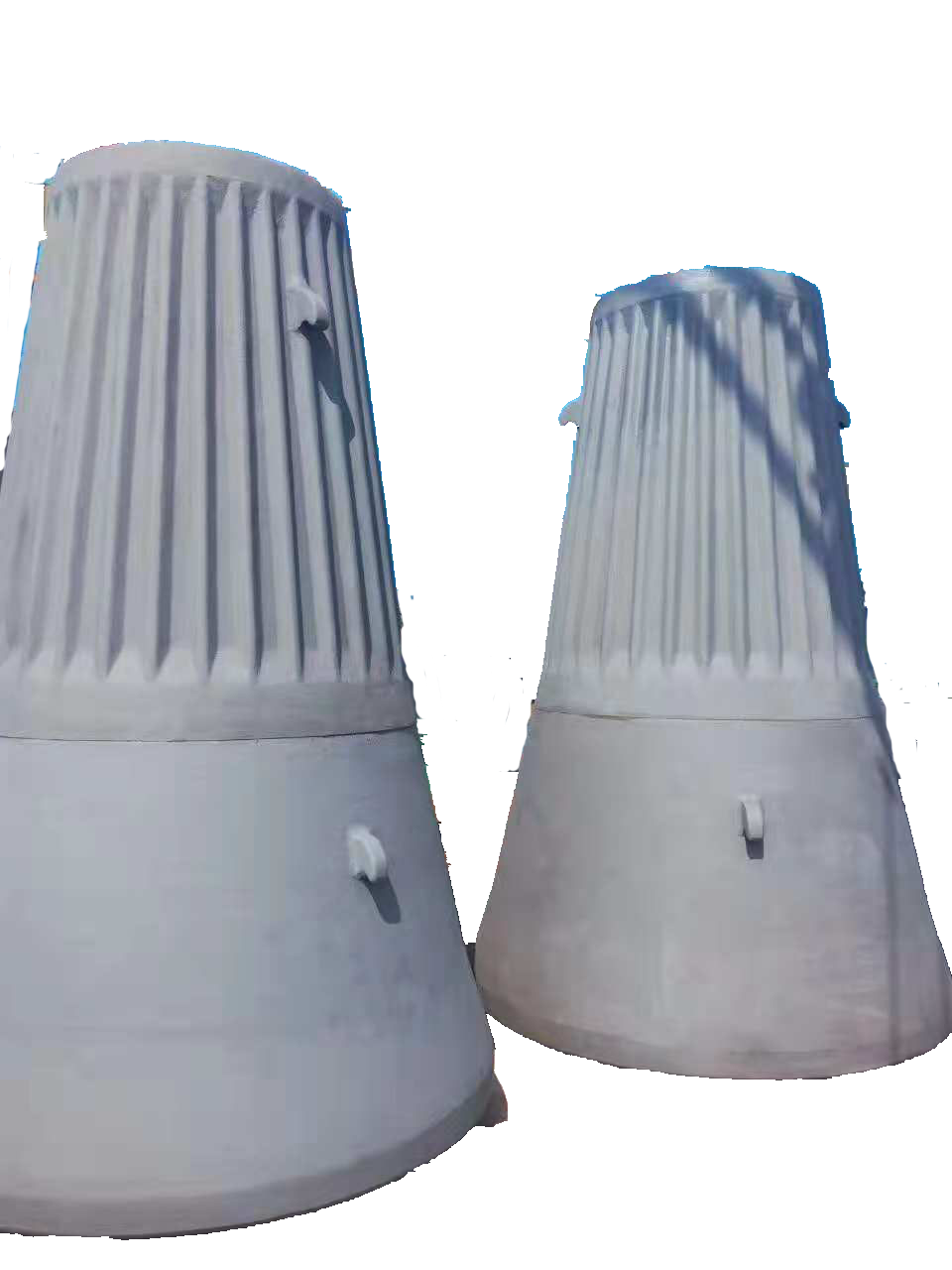

- Gyratory crusher mantle

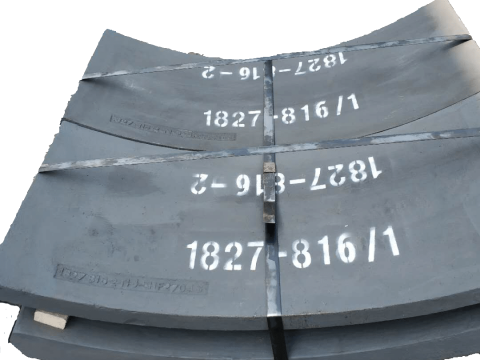

- Gyratory crusher concave segments

Qiming Machinery’s proprietary alloys and innovative designs result in longer wear life compared to other OEM replacements.